Street Repaving with a Sustainable Twist – Right Outside My Door

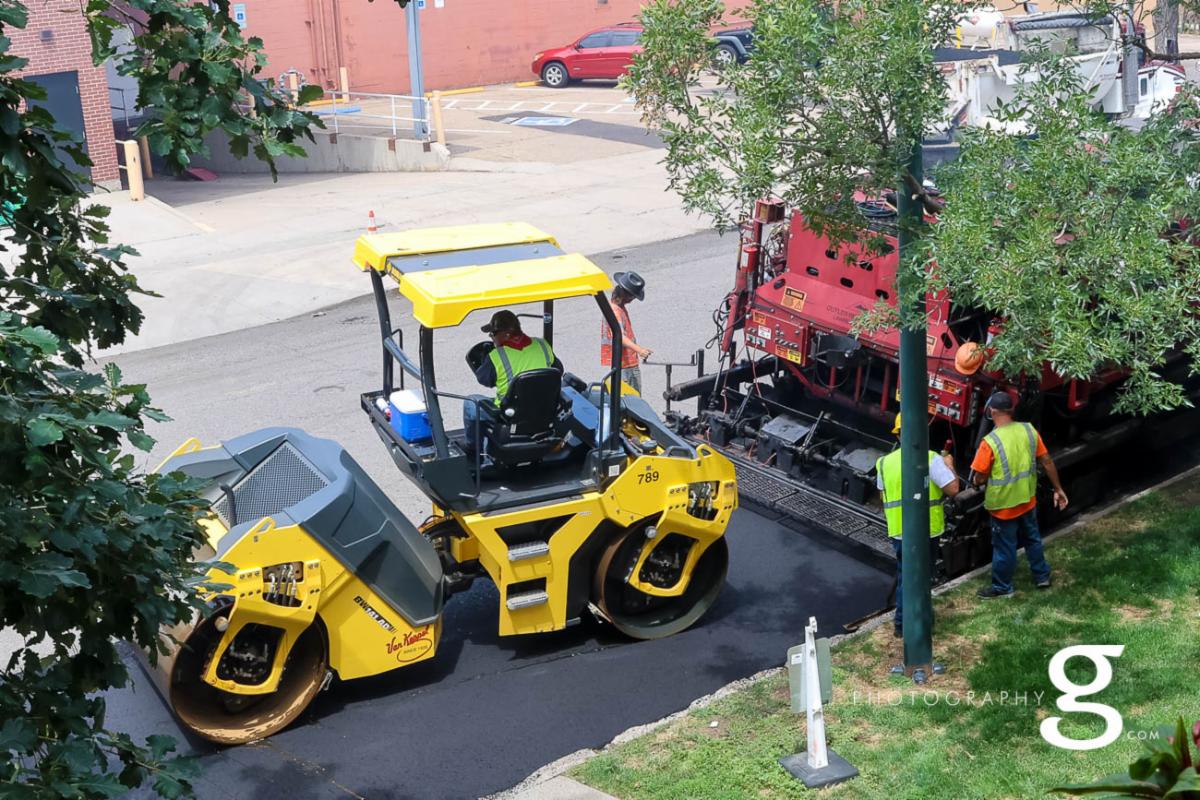

This summer, I had a front-row seat to a fascinating process: street repaving with recycled asphalt—right outside my home in Denver. From the comfort of my deck, I watched as a dedicated team from Cutler Repaving out of Lawrence, Kansas brought new life to our worn-out street using an innovative method that’s as smart as it is sustainable.

Instead of ripping up and hauling away the old asphalt, Cutler’s process heats and rejuvenates the existing surface, blending it with new material and laying it back down—all in a single, continuous motion. The result? A smooth, durable surface with far less environmental impact compared to traditional methods.

Even more impressive than the machinery was the crew itself. These workers battled the mid-day heat with grit and professionalism, always quick with a smile or a wave. I had a chance to meet several of them and was struck by their friendliness and work ethic. Watching them in action was both educational and inspiring.

This project is a great reminder that infrastructure improvements can be sustainable, efficient, and community-minded. Not only did we get a better street, but we also reduced waste, minimized traffic disruption, and supported a company pioneering greener methods in road construction.

Hats off to Cutler Repaving and the team on the ground for a job well done—and for showing how innovation and hard work go hand-in-hand.

Want to learn more about how asphalt recycling works? Visit cutlerrepaving.com to see their process in action.